National Research Council

Category Archives: [:it]Sistemi per la produzione di energia distribuita[:en]Distributed energy production systems[:]

- 16

Nov 15

-

- 11

Nov 15

-

Electrochemical systems for energy generation and storage in automotive and steady-state applications

Electrochemical and spectroscopic techniques are used for fuel cell performance and reliability investigation. The balance of plant (BoP) components integration and management are analyzed for small size systems (4-20 kW). H2 storage and CO2 capture processes are investigated by adsorption on solid materials.

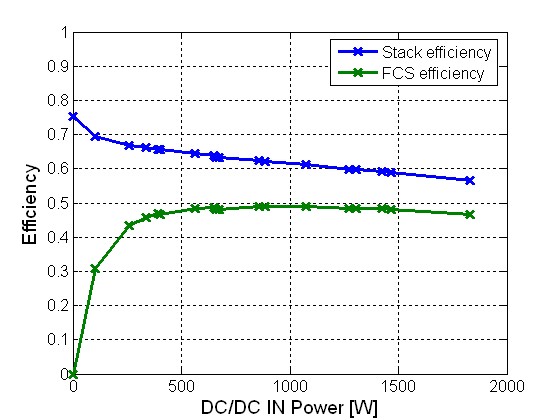

Efficiency curves of a 2,4 kW PEM Stack and overall Fuel Cell System

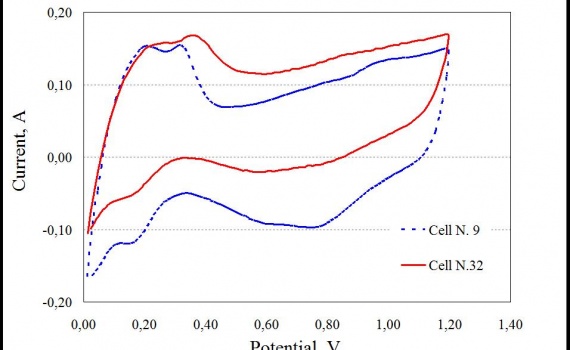

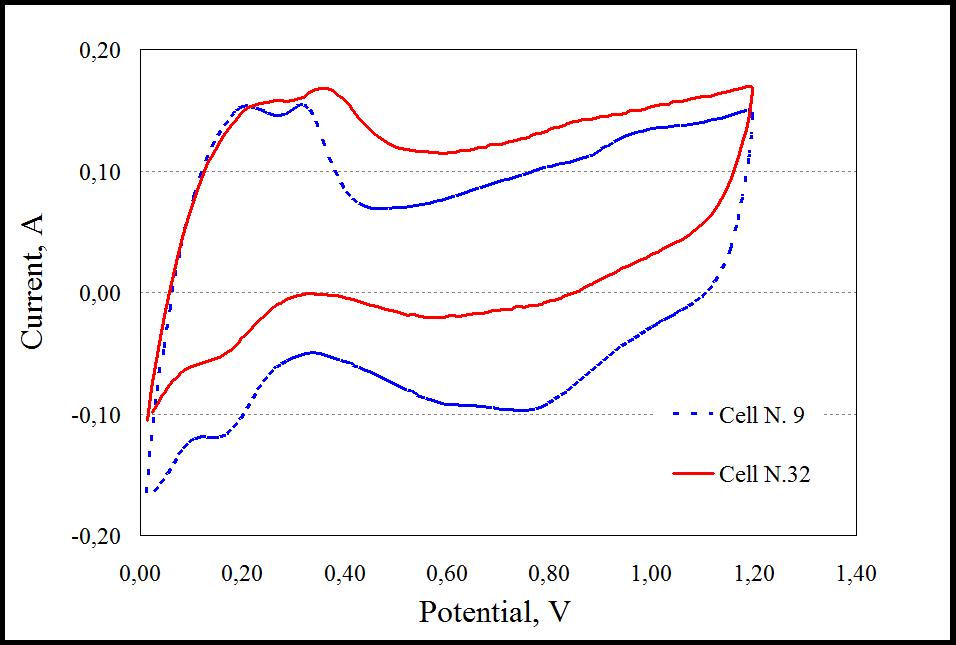

Cyclic voltammetry curves for two cells of a 500 W PEM stack

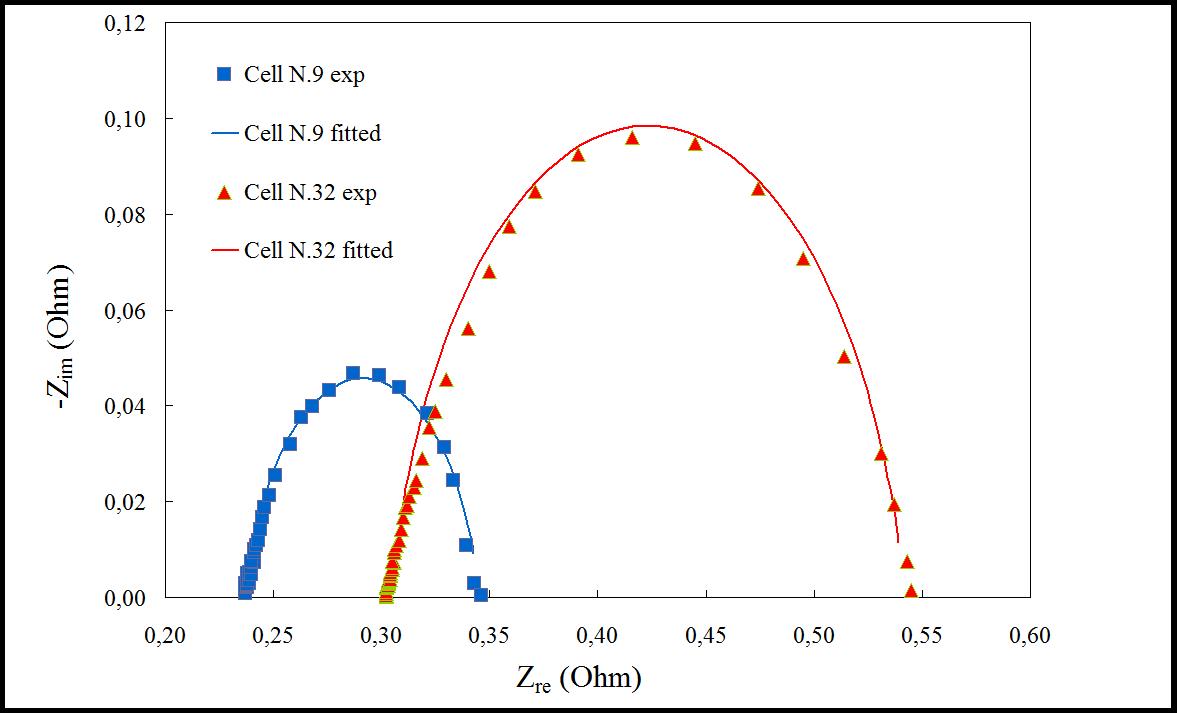

Nyquist plots for two cells of a 500 W PEM stack

- 11

Nov 15

-

Characterisation of bio-derived gaseous fuels

Assessing properties of biogas and syngas as biomass-derived alternative fuels, as a function of composition and operating conditions. The activity is aimed at suggesting guidelines (design specifications and operating strategies) for the development of high-efficiency, ultra low-emission combined heat and power (CHP) systems.

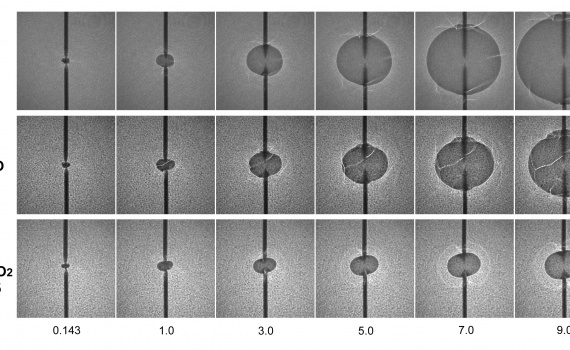

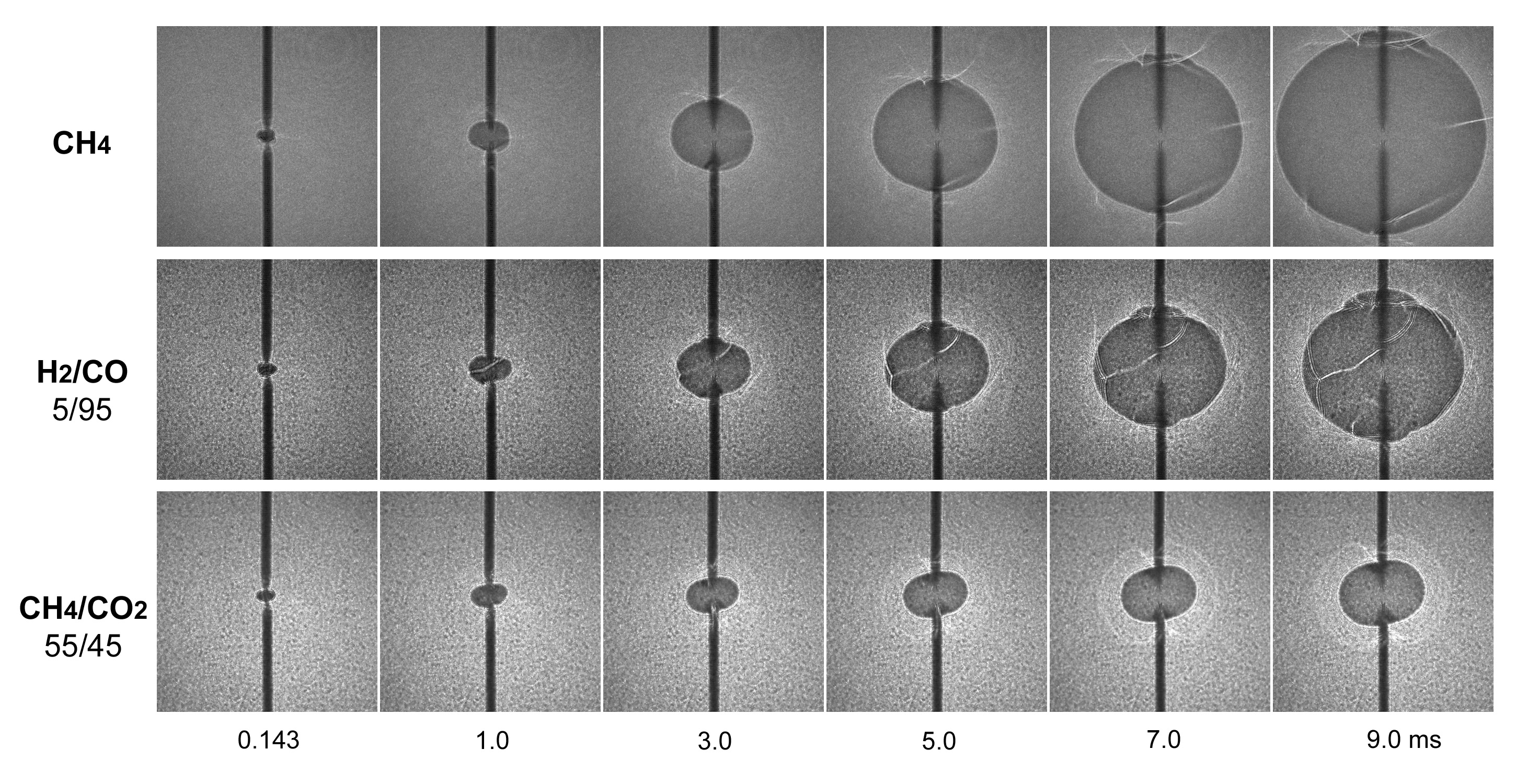

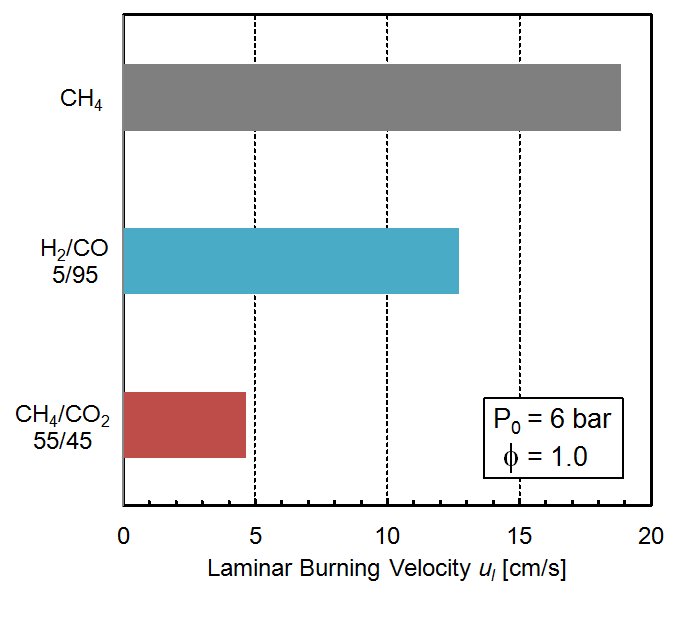

Flame propagation for methane, syngas and biogas (P0=6 bar, Φ =1.0)

]

]

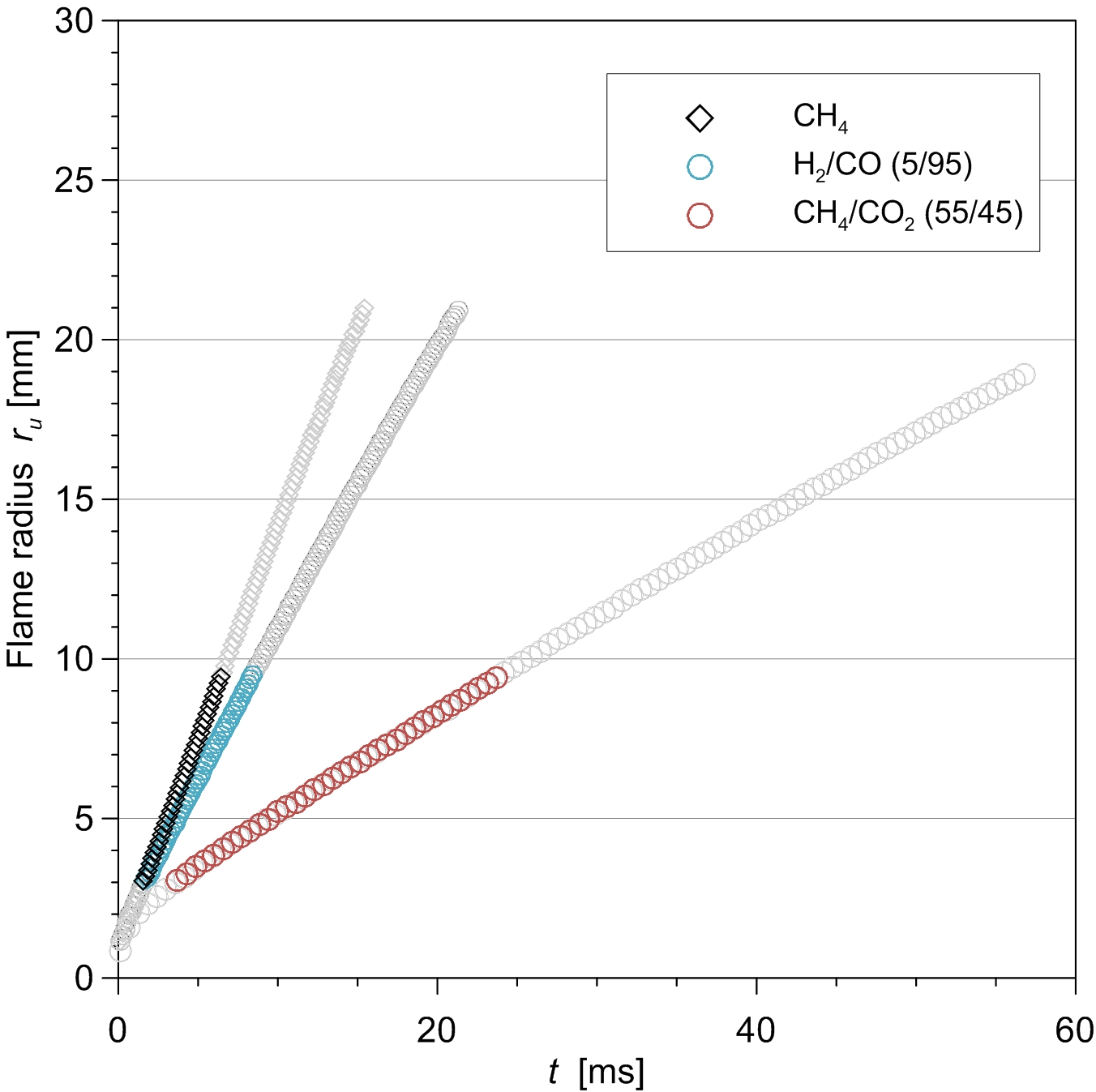

Time evolution of flame radius for methane, syngas and biogas (P0=6 bar, Φ =1.0)

Laminar burning velocity for methane, syngas and biogas (P0=6 bar, Φ =1.0)

- 29

May 13

-

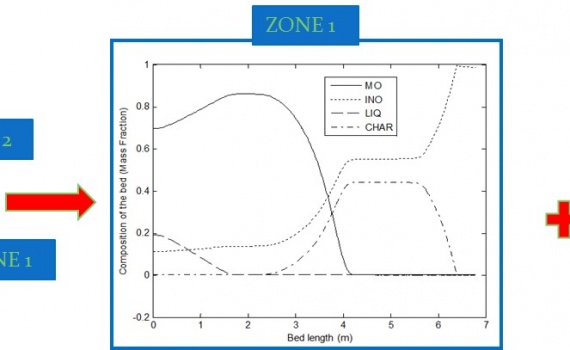

Stationary Systems of Energy Production

The Institute is also active for the study of the fuel-cell applications within the frame of stationary production related to electric power generation and thermal energy.

- 29

May 13

-

Hybrid Propulsion Systems

High Efficiency Energy Systems for Transport Applications

Road transport and power plants for energy production are almost entirely dependent on fossil sources and are considered responsible of a significant and growing share of CO2 anthropogenic emissions. The objectives of decarbonisation, energy security and urban air quality can be achieved by the development of novel energy systems able to break the link between fossil fuels and energy production, improve fuel economy and reduce emissions.

The hybrid vehicles equipped with a “thermo-electric” propulsion system represent an evolution of traditional vehicles in which a single internal combustion engine is present. The main advantage of the double propulsion consists in exploiting the high efficiency characteristics of the electric engine in the transitory phases, allowing the thermal engine to run at conditions close to those of maximum efficiency, and improving the driving range with respect to battery powered electric vehicles.

Polymeric electrolyte fuel cells fed by hydrogen are a promising long term alternative to internal combustion engines for application to hybrid electric vehicles. This is due to their high efficiency in a wide range of load conditions and absence of exhaust emissions.The research activities of the Istituto Motori in the field of hybrid power trains are carried out within the frame of the following issues:

- study of energy flow simulation models and optimal control strategies for different configurations of thermo-electric propulsion systems

- design, realization and experimental characterization of fuel cell systems fed with hydrogen

- experimental characterization on driving cycles of fuel cell power trains, analysis of energy flows and efficiency optimization as a function of hybridisation level between the on board systems for generation and storage of electric energy (from range extender to full power configurations)

- experimental study of different battery typologies and supercapacitors for electric energy storage on board of hybrid vehicles

- study of catalytic processes for hydrogen production from liquid and gaseous fuels

- study of technologies for on board hydrogen storage.

Facilities of laboratories include fuel-cell systems up to 30 kW, electrical drives up to 80 kW, different typologies of batteries and supercapacitors, dynamic brakes for the simulation of driving cycles up to 120 kW, laboratory plants for hydrogen production and for the study of adsorption properties of solid materials for hydrogen storage.

- 27

May 13

-

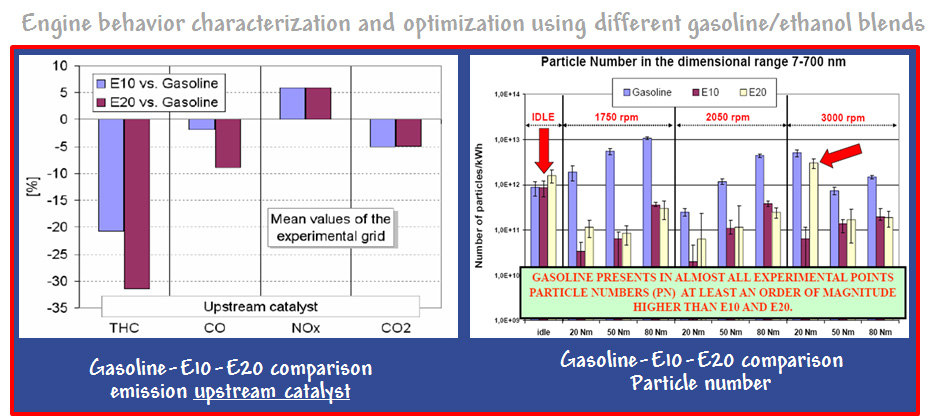

Fuels

During the last decade, alternative fuels have had a larger diffusion, especially in niche applications. Recent European energy policy has promoted the diffusion of renewable energy sources to reduce greenhouse gases (GHG) from fossil fuels. In this context also biofuels production has increased.

The problems of land use competition with primary human needs, connected to the first generation biofuels , will be reduced by the second generation biofuels. In fact they allow efficient production processes to convert biomass from not-food crops. Further improvement are expected from the assessment of the third generation biofuels obtained with low energy input, and with high yield, from marginal or unproductive land.

Also fossil sources could be used to produce reformulated fuels for transports. The second generation technology itself could be used to convert natural gas in hydrogen or GTL (Gas to Liquid, used in compression ignition engines) or, to convert coal in SNG or H2, or CTL (Coal to Liquid, also used in diesel engines). In both cases (production of liquid or gaseous fuels for transport), with fossil sources as feedstocks, not necessarily a better well to wheel GHG emission could be achieved, as from biomass feedstocks.

Gaseous fuels, (LPG, CNG and hydrogen, when available from an energetically convenient point of view) can reduce pollutant emissions at the exhaust of engines. Anyway the problems in supplying and storing hydrogen on board vehicles must be taken in account, because of its density, about one order of magnitude lower than NG, implying an appreciable autonomy range reduction.

Therefore CNG and hydrogen, or their blends, can be used successfully in “closed” vehicle parks in urban areas (public transport, distribution of goods, waste collection).

In Istituto Motori research activities are actually in progress for:

- Biodiesel and bioethanol, particularly in blends with diesel oil and gasoline;

- Natural gas and H2 blends;

- Liquid natural gas (LNG)