Compression Ignition Engines

Engine Technology: toward “Near Zero Emissions” c.i. engines

Based on its better thermodynamic efficiency with respect to the spark-ignition (SI) engine, the compression ignition engine will be the most attractive powered solution for different classes of vehicles.

The key-word for the development of the future CI engines is “flexibility”, in terms of performance, operating mode, hardware complexity and adopted fuel.

In Istituto Motori studies and experiments are performed on various aspects of the CI engine technology and in a wide range of engine applications as:

- Low temperature combustion concepts to accomplish the in-cylinder NOx and particulate formation control;

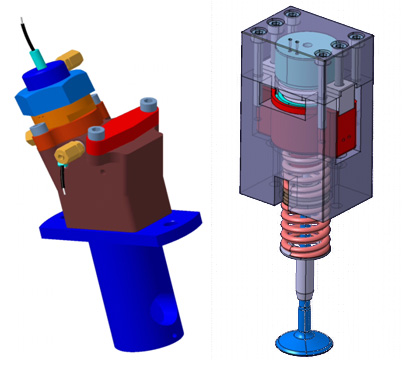

- Development of base combustion system technology like high-pressure injection systems, piston bowl design and compression ratio, intake port design in order to increase performances and reduce emission and NVH;

- Advanced air, boosting and EGR management systems, like twin-stage turbo and low-pressure EGR, to obtain better performances and fuel economy;

- Advanced after-treatment systems, like catalysts and filters for unburned gaseous, nitrous oxide and particulate matter emission control, to comply with the severe pollutant limitations without penalties in engine performance